Department of Anatomy and Cell Morphology, University of the Orange Free State, Bloemfontein, South Africa

The aim of this study was to devise a practical and inexpensive labelling system for plastinated prosected specimens. Letters printed in various colours are punched in either a round or a pointed shape by means of a specially constructed punch and subsequently glued onto the specimen. The final product is clearly labelled and valuable for purposes of learning or examination.

Equipment, Specimen Labelling

Willem F. Pretorius, Department of Anatomy and Cell Morphology, Faculty of Medicine, University of the Orange Free State,339 Bloemfontein 9300, Republic of South Africa. Telephone: 27 051 405 3552 /Fax: 27 051 430 9282. Email: GNANBGO@med.uovs.ac.za

![]()

Development of Technology is always followed by a vast number of challenges. Plastination of prosected material has left the technician with the challenge of how to identify or label the different structures (Jackson, 1987). The aim of this study was to develop a labeling system for prosected plastinated specimens.

Alphabet letters are printed on 0,5mm thick Poly vinyl chloride (PVC) sheating. This is done by using a hot lead block containing an alphabet. Pigment stamping foil is used to print the letters onto the PVC (Brune, 1987). The PVC is cut to a size of 150mm x 70mm to make handling easier. The letters are spaced 5mm apart and are 3mm high from top to bottom.

A special punch was made as can be seen in figure 1. The letters are visible through the top die plate (figure 2) of the apparatus and the letter may be centralized before punching. The punching is an easy process. The punch moves from below and pushes the letter through the die plate to the top (figure 3). The round punch used here has a diameter of 4mm. To produce arrows a pointed punch was made. These pointed markers use the same alphabet and are used to indicate small structures without obscuring them (figure 4).

The lettered discs are secured onto the prosection using household clear silicone. A thin layer of silicone coates the top surface of the disc as well. Because some specimens are large with more structures, more than one alphabet may be required and the solution to this problem was to print alphabet-letters of various colours, using different coloured pigment stamping foil on the white PVC.

This labelling system was found to be very practical and we even used these discs (labels) on the bottled prosections (wet specimens). Cyanoacrylate glue was used in the case of bottled specimens to attach the labels onto the prosection. The letters are easily identifiable and, due to the small dimension of the disc, it seldom obscures structures. The glue is of lasting quality and very few cases of re-application have occurred.

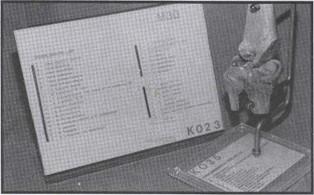

Figure 5. The legend can be taped to the transparent base. Alternatively, the legend is mounted in a perspex stand.

Because only letters and arrows are used on the prosected specimens, without names, these specimens may also be used for spot tests. Next to the specimen in the study center (museum) is the legend enabling the student to identify the structure he is looking at (figures 5 and 6). Finally, a specialized engineering shop will be able to manufacture these punches and apparatus at a very low cost, making this identification method very cheap.

Brune EO: Labelling structures and eliminating air bubbles in fluid mounted specimens. J Audiov Media Med 10: 72-74, 1987.

Jackson RL: Durable labels for plastinated specimens. J Int Soc Plastination 1(2): 9-11, 1987.

https://doi.org/10.56507/DMJV3080