1 College of Veterinary Medicine, The University of Tennessee, Knoxville, Tennessee, USA.

2 State Anatomy Board, University of Maryland, Baltimore, Maryland, USA.

3 College of Veterinary Medicine, Iowa State University, Ames, Iowa, USA.

The popularity for use of band saws in preparing plastinated specimens has increased significantly over the past few years. This use has brought forth many modifications that have facilitated the production of even higher quality specimens. In this study, a Shark Band blade was evaluated and found to be superior over more commonly used (10 to 12 teeth per inch) blades. Trials were performed upon frozen tissues in preparation for S10 plastination, E12 sheet plastination, as well as for slicing cured S10 plastinated whole brains. The advantage of a Shark Band blade is, that by a reduction to only 3 teeth per inch, the creation and subsequent contamination of specimens by sawdust is significantly reduced. The minimal set and thickness (14 gauge / .014 inches) of the teeth and blade similarly promotes a smooth and very fine cut. The effects of this blade can be even further enhanced through an increase in the blades cutting speed. Unfortunately, the same design that facilitates the quality of the cut also greatly reduces the blade life. When cutting dense bone or enamel, the blade teeth are quickly dulled and taken out of set. This necessitates the replacement of the band after only a few cuts.

Shark Band, Plastination, Bandsaw

Dr. R.W. Henry, College of Veterinary Medicine, The University of Tennessee, 2407 River Drive UT/CVM, Knoxville, Tennessee, 37996-4500, USA. Telephone: 423 974 5822 / Fax: 423 974 8222. Email: RHenry@UTK.EDU

![]()

A smooth flat surface on sliced anatomical specimens provides for greater clarity of detail and for an aesthetically more appealing end product. A handsaw is commonly used for cutting specimens. Several factors influence the quality of the cut. These factors include saw setup, blade setup, maintenance, and type of blade.

The saw must be set up properly with the blade perpendicular to the table and parallel to the fence. Blade guides should hold the blade in this position without distortion of the blade path. If possible, blade guides should be adjusted so there is no room for lateral blade movement within the blade guides. Some types of guides are not adjustable for lateral play and should be replaced as they wear. Most blade guides are adjustable for blade width. The front of the guide

should be adjusted to the bottom of the blade gullet to pre- vent the guides from removing the set from the blade. On some saws, blade speed can be adjusted to match blade type. Faster blade speeds with the appropriate blade can maximize blade performance.

Proper placement of the blade on the machine helps to ensure the best possible cut. It should be centered on the pulley wheels so that it will run true. The pulley tires that cover the wheels should be clean and in good condition. Appropriate tension should be placed on the blade. Too much tension results in blade breakage and machine wear, while too little tension allows the blade to waver. Most owner manuals will have tension recommendations, but the best tension will depend on fixed characteristics, such as pulley diameter and blade length as well as variable factors, such as blade gauge (thickness), blade width, and type of material being cut.

Blade set produces a cut wider than the width of the back of the blade and prevents binding of the blade. The set of a blade is proportional to its thickness. The blades are set by bending the points of adjacent teeth in opposite directions out of the plane of the blade. The teeth points are bent so that the amount of material removed by the blade (kerf) is two to three times the blade width. A thinner blade re- quires less set and produces a smoother cut since the sur- faces cut by adjacent teeth are closer to being in the same plane. Blade set is also important for making straight cuts. If the set is asymmetrical, the blade will tend to pull toward the side with the greatest amount of set.

Blades should be clean, sharp, and with appropriate set. Dull, dirty, or out of set blades will cause the blade to waver or bind. Dull blades or blades out of set can be reconditioned, but the cost is usually a substantial portion of a new blade cost. If material is sticking to the blade or it becomes greasy, blade performance will be diminished and the blade should be cleaned. Warm soapy water is generally sufficient to restore blade performance.

The type of blade is a major factor in the quality of the cut. Bimetal blades are commonly used. This type of blade has a soft metal back that helps reduce breakage as the blade is bent around the pulley wheels. Welded to this back are hardened teeth which stay sharp longer than the soft metal would. For most materials, wider blades and more teeth per inch produce smoother cuts. Narrow blades allow for tighter turns when cutting curved shapes. Tooth style can be standard, shark, or hook. Standard toothed blades have a triangular shaped tooth with a deep space (gullet) between each tooth. In shark tooth blades, the gullet is shallower. Hook tooth blades have a hook-like point that pulls the blade into the material.

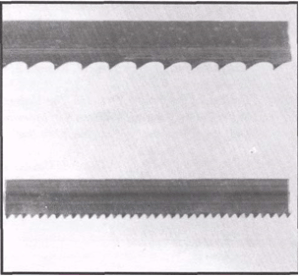

Figure 1. A Shark Band handsaw blade (top) in comparison to a standard 10 tooth/inch bandsaw blade (bottom).

The Shark Band blade (5/8 wide, 14 gauge, and 3 teeth per inch) (Holly Sales and Service, Craig Simms, 6310 Howard Lane, Elridge Industrial Park, Elkridge, Maryland, 21227, USA. Tel: 410 796 7474) and a commonly used blade (1/2 inch wide, 25 gauge, and 10 teeth per inch) (figure 1) were compared while preparing a whole human head for E12 sheet plastination. The head was frozen and sliced into sections approximately 2.5mm thick. Sections were then prepared for El2 plastination by removing sawdust, dehydrating and degreasing in acetone, impregnating the slices with E12 polymer, then casting the impregnated slices into a thin sheet of casting resin and cured (Weber and Henry, 1993). The final cured sections cut with each blade were then qualitatively evaluated for smoothness of cut and general appearance.

The Shark Band blade was also used to make other types of cuts commonly done in a plastination lab. A midsagittal section of a frozen fetal goat (figure 2) was sliced with the Shark Band blade and subsequently plastinated using the standard S10 technique (von Hagens, 1986). A whole equine brain that was plastinated using the S10 technique was sliced (figure 3) with the Shark Band blade after curing (Weiglein, 1996). These specimens were then qualitatively compared for smoothness of cut and general appearance with similar specimens previously prepared with the standard 10 tooth per inch blade.

The influence of blade speed on blade performance was also evaluated by qualitatively comparing the appearance of similar specimens cut at different blade speeds. The machine used did not have intrinsic speed adjustment, but adaptions were made which allowed for testing of different blade speeds. These adaptions could be implemented by either changing the saw motor or by changing the motor pulley diameter size.

Cutting specimens with the Shark Band blade required less force on the specimen against the blade than the same cuts with a standard blade. The specimens cut with the Shark Band blade (figures 2-5) had less sawdust residue on the finished slices than specimens cut with the 10 teeth per inch blade. The surface of all specimens cut with the Shark Band blade had a smoother appearance than those cut with the other blade. Both frozen specimens and previously plastinated specimens consistently showed these results. Increasing blade speed with the Shark Band blade resulted in increased performance of this blade.

With both blades, blade performance decreased with use as blades became dull and/ or lost set. More force was needed to feed the specimen into the blade and the ability to cut dense material may be lost. The blade was more likely to waver and cut at an angle to the direction of feed. These problems resulted in uneven or tapered slices. Performance loss was most evident when cutting dense bone or tooth enamel. This loss of performance was noticeably more rapid with the Shark Band blade than with the standard blade.

The Shark Band blade produces a better quality of specimen than the standard blade. This improved quality of the cut is probably due to the thinness of the blade and to the increased length of the gullet. The length of the gullet is increased as the teeth per inch decrease. For many materials, an increase in teeth per inch produces a finer cut. For cutting anatomical specimens, this does not appear to be true. Sawdust produced when cutting frozen or plastinated anatomical specimens is often tacky and readily sticks to the blade. This can clog short gullets resulting in poor blade performance. The longer gullet of the Shark Band blade may remove the sawdust more readily and allow for a smoother, cleaner cut.

The set of a Shark Band blade may also play a role in its superior performance. The band is thinner than similar blades and is set narrower than other blades. This reduced set first reduces the overall amount of saw dust produced or, expressed in physical terms, reduces the work the blade has to perform doing the same cut. This, therefore, allows for both a faster blade speed and faster feed. In turn, the higher blade speed may help to more efficiently remove the saw dust. The reduced set likely contributes to the finer cut, while the narrow gauge likely reduces blade life.

In making anatomical preparations, the most important factors for smooth, clean cuts is a properly maintained and tuned bandsaw with clean, sharp and appropriately set blades. Choice of blade type also contributes to the quality of the preparation with the Shark Band blade providing a superior cut. This increased quality of the cut comes at the expense of reduced blade life as compared to more standard blades. Considering the cost and time involved in the preparation of plastinated specimens, the reduced blade life is a reasonable price for the increased quality of the specimens produced.

von Hagens G: Heidelberg Plastination Folder: Collection of all technical leaflets for plastination. Anatomische Institut 1, Universitat Heidelberg, Heidelberg, Germany, 1986.

Weber W, Henry RW: Sheet plastination of body slices - E12 technique, filling method. J Int Soc Plastination 7: 16-22, 1993. https://doi.org/10.56507/EZGX2343

Weiglein A: Preparing and using S-10 and P-35 brain slices. J Int Soc Plastination 10: 22-25, 1996.

https://doi.org/10.56507/IXGV4189