Department of Anatomy and Cell Biology The University of Michigan 3626 Medical Science II Ann Arbor, Michigan 48109-0010

As part of a complete renovation of the anatomical morgue facility at The University of Michigan, a new embalming station was planned by the author and a colleague. The unit was built by the Lipshaw Corporation of Detroit, Michigan. It was intended to do the following:

In addition, it was felt that certain other features were desirable:

Routine use has shown that this system fulfils the basic requirements and accommodates all of the additionally desirable features.

embalming; cadaver; preparation;

Arthur Rathburn, LFD Department of Anatomy and Cell Biology The University of Michigan 3626 Medical Science II Ann Arbor, Michigan 48109-0010

![]()

As part of a complete renovation of the anatomical morgue facility at The University of Michigan, a new embalming station was planned by the author and a colleague. The unit was built by the Lipshaw Corporation of Detroit, Michigan. It was intended to do the following:

In addition, it was felt that certain other features were desirable:

Routine use has shown that this system fulfils the basic requirements and accommodates all of the additionally desirable features.

RINSING AND DRAINAGE

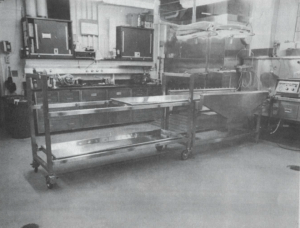

The station is composed of two sinks with an intervening platform for the embalming machine and a tall splash shield to deliver supporting utilities. The left sink receives drainage from a specially-designed body tray. During embalming, the walls of this tray are continually rinsed by encircling water jets. Drainage is conducted to a heavy-duty waste grinder in the sink. A hydro-aspirator is mounted at the left of the sink and drains into it via polyethylene tubing.

The right sink is a deep handsink. An eye- wash station is installed on the splash shield above it and a power spray hose is mounted in front. A removable, stainless steel perforated panel (24" x 36") is included and can be placed over this sink if additional work area is needed.

Another panel of identical dimensions is located between the sinks and supports the embalming machine. Located on the splash shield above the embalming machine are two special taps. One is connected to a stainless steel line that delivers embalming fluid from bulk storage in another room. The other is connected to a distilled water line. Embalming fluid can thus be mixed directly and conveniently in the reservoir of the embalming machine. A waterproof electrical outlet is located in this area of the splash shield to supply power to the machine. Directly beneath the embalming machine is the instrument drawer. This location has proven quite convenient for the operator.

FUME PROTECTION

The second major component of the embalming station is the tray support. This is essentially a stainless steel rack installed perpendicular to the sinks. It incorporates five rollers on each side, intended to receive a body tray from a mobile carrier. The edges of the tray are formed into a reinforced flange and support the weight of the body and the tray on the rollers.

Two exhaust ducts, 1 inch in width, are installed along the entire length of the tray support and join beneath the tray. Contaminated air is conducted under and behind the sinks, where it is vented to the outside via the exhaust system for the building. Because formaldehyde vapors are more dense than air (formaldehyde = 1.067 x air), the intake openings were positioned lateral to the body. Vapors are thus drawn off before they drift past the face of the operator. This is particularly important considering the possible carcinogenic effect of formaldehyde.

WATER AND ELECTRIC SERVICE

Also installed in the tray support are two cold-water tubes extending the entire length of the body tray. These tubes, one on each side, are equipped with a series of water jets, spaced 4 inches apart. They are supplied through flexible hoses from the sink, equipped with quick-disconnects. The water tubes are hinged and may be operated in a raised or lowered position, as needed.

Electrical outlets are located on both sides of each end of the tray support for operation of hair clippers, Stryker saws and other electrical instruments. An instrument stand is mounted on the tray support near the sink and swings out, over the body for easy access. A large fluorescent light fixture, positioned directly over the body, provides illumination.

EMBALMING PROCEDURE

A two-body, mobile carrier is used to transport the body to the tray support. The water jets are raised and the tray, containing the body, is rolled onto the stand and clamped in place. The water jets are lowered, taking care that none of their openings are blocked by the body. Rinse water is then turned on for the duration of the procedure.

The body is cleaned, shaved and prepared for embalming. The embalming fluid tap is opened and a measured amount of fluid is run into the embalming machine. This is followed by an appropriate amount of distilled water. The body is then embalmed and allowed to drain overnight with the rinse water running in both the tray and the sink. The following day, latex is injected and the body tray rolled back onto the mobile carrier and taken to the storage room. Here, it is rolled onto the tray support of the cadaver lift, moved to an appropriate position in our mortuary rack and rolled into place for storage.

CONCLUSIONS BASED ON OUR EXPERIENCE

The University of Michigan processes about 300 cadavers per year to supply the needs of the medical and dental teaching programs, as well as other local academic institutions and hospitals. Before acquiring this new equipment, autopsy and embalming was considerably more difficult and inconvenient. Also, the institution of adequate safety procedures was virtually impossible. Three features of this new station have proven most important in alleviating these difficulties. The new transport system permits the body to be positioned on the same tray from the time it is received until it is placed in storage. This represents an enormous reduction in physical labor. The hinged, bilateral rinse-jet system permits continual flushing, thereby keeping the work area clean and sanitary. And, finally, the laterally positioned fume-exhaust ducts remove formaldehyde and other noxious vapors before they rise to expose the operator.

|

|

none