Department of Anatomy, Shanghai Medical University, Shanghai, P.R. China.

According to the standard plastination procedures, the dehydration by freeze substitution in acetone is normally achieved at -25°C and the forced impregnation of specimens at -15CC to -25°C in a deep freezer. Now, we have been able to modify the dehydration procedure and use room temperature for dehydration. We also developed a new silicone polymer that can be stored and used for impregnation at room temperature (10 to 25°C). An acetone filter (or recevery) system was also designed to remove some acetone before the acetone reached the pump. Many high quality gross anatomical specimens have been prepared this way. They have remained in good condition and retained stable color for five years. This paper will also describe the differences regarding equipment needs for plastination at room temperature compared to plastination at -25°C.

Presented in part at the 9th International Conference on Plastination, Trois-Rivieres, Canada, July 5-10, 1998.

room temperature, intermittent vacuum, Su-Yi Chinese silicone

Zheng Tianzhong, Department of Anatomy, Shanghai Medical University, Shanghai 200032, PR.. China. Tel: 86 21 6478 2982 / Fax: 86 21 6478 2982. Email: tizhengc@online.sh.cn

![]()

In the standard plastination procedures, originally developed and described by von Hagens (1986), dehydration of specimens is normally achieved by freeze substitution in acetone at -25°C. Forced impregnation is also carried out in a deep freezer at -15°C to -25°C. Plastination experiences at room temperature have been previously reported but were not judged satisfactory because the silicone used at this time polymerized too rapidly at room temperature and leaded to expensive loss of polymer (Cook and Dawson, 1996). Successful room temperature dehydration with acetone (Henry et al., 1998; Zheng et al, 1998) and impregnation with polymer designed for room temperature plastination (Zheng et al., 1996; Henry, 1998; Glover et al., 1998; Zheng et al., 1998) have also been reported recently. We have developed a procedure that successfully allows dehydration with acetone as well as impregnation to be carried out at room temperature (15 to 20°C). We have utilized intermittent vacuum procedure instead of the continuous vacuum procedure described by von Hagens (1986). The use of a new silicone named the Su-Yi Chinese silicone (Nanjing Su- Yi Plastination Factory, 49 Ning Lie Road Ka Zi Men, Nanjing 210012, China) developed in 1996 permits this plastination procedure at room temperature.

Fixation

Human internal organs (heart, liver, spleen, trachea, brain and kidney), muscles with joints (shoulder joint and knee joint), fetuses (different sizes and ages) and some pathology specimens (lung and colon cancer) were fixed by immersion in 7% formalin for 10 days at room temperature, then kept in 5% formalin at room temperature for 1 month. Fixation was performed in plastic containers with tight lids.

Dehydration and degreasing

After fixation the specimens were rinsed in running tap water for 3 days. The specimens were dehydrated in a graded series of acetone solutions (50% - 60% - 70% - 80% - 90% - 95% - 97% - 98% - 99% - 100%) at room temperature. The volume ratio between the specimens and the acetone solutions was maintained at 1:10. A direct reading acetonometer (figure 1) (RTE Electronics Ltd, O.BOX 8555, 128 Reykjavic, Iceland and Nanjing Su-Yi Plastination Factory, China) was used to monitor the acetone concentration everyday, after thorough mixing of the acetone bath. The specimens were moved to the following acetone bath when equilibrium was achieved. The specimens were brought to the 100% acetone bath and dehydration was considered complete when the acetone remained at 100% for 5 days. Room temperature dehydration permitted degreasing of the specimens during the same time.

Impregnation

Impregnation was divided into 3 stages, all done at room temperature.

Pre-impregnation

After dehydration and degreasing, specimens were submerged into the Su-Yi Chinese Silicone solution at room temperature for 3-5 days which allowed excess acetone to escape and the specimens to equilibrate with the silicone solution naturally without force. During this stage the specimens were moved and turned every day. Weights were necessary to keep the specimens submerged. No special equipment was required for this step. One only needs containers (plastic or stainless) large enough to completely submerge the specimens.

Intermittent forced impregnation

After pre-impregnation, the specimens were transferred to a vacuum chamber (figure 2) designed and built by the Nanjing Su-Yi Plastination Factory. The 1.9M long by a 0.8M diameter chambers permitted impregnation of whole cadavers as well as parts.

Daily vacuum was established, and the pressure slowly decreased. Vacuum was applied 4 hours in the morning, then stopped 1-2 hours for the lunch time and applied again 3-4 hours in the afternoon. Before the end of each working day the vacuum pump was turned off and the vacuum released. The chamber was then opened to allow the specimens to be moved around to relax and further equilibrate with the silicone solution for 14 to 15 hours.

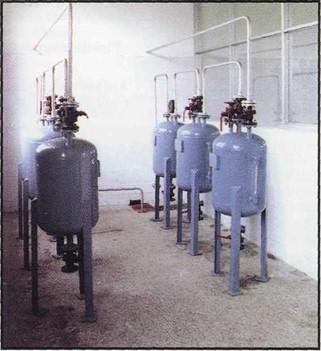

Over a period of 12-15 days, the pressure was gradually lowered to 7.5 mm Hg. The vacuum was maintained for 3-4 more days until no more acetone gas bubbles appeared. This indicated that there was no more acetone remaining in the specimens. An acetone gas filter system was designed and used to protect the vacuum pump and decrease pollution. The acetone gas filter system consisted of two phases. The first phase (figure 3) was installed

Figure 3. Stainless containers located between the vacuum chambers and the pumps to collect acetone vapors.

between the vacuum chamber and vacuum pump. It is made of three stainless containers. The middle container contains water to absorb the acetone vapors. The other two containers protect the vacuum chamber and vacuum pump. They prevent the acetone contaminated water to be aspirated in the pump or to be aspirated in the chamber if the pump is accidently stopped. The second phase was installed at the end of the exhaust pipe of the vacuum pump, for the purpose of decreasing air pollution by filtering oil and acetone fumes.

Post-impregnation

After intermittent forced impregnation, the specimens were moved from the vacuum chamber but kept submerged in the silicone solution for 3-5 additional days.

Curing

Curing was also done at room temperature. The specimens were removed from the silicone bath and wiped of the excess silicone. The specimens were slow cured by covering their surface with old silicone mixed with varying ratios of hardener (1-5%).

Samples of liver, spleen, trachea and kidney were taken for histological study before and after plastination. The samples from plastinated specimens were placed into 70% acetone to remove silicone. They were moved in a graded ethanol series (70%, 95%, 100%), paraffin embedded for routine histology, stained with H-E, examined and photomicrographs were taken.

After plastination at room temperature, the internal organs (heart, liver, spleen, trachea, brain and kidney), joints and soft tissues retain their original shape and colors and are still flexible. They have no odor or toxicity. By using room temperature, dehydration and degreasing are complete for most specimens in about 3-5 weeks. The sizes and diameters of the specimens were measured before and after plastination to evaluate the shrinkage and shrinkage of specimens was less than 5%. Flexibility of the specimens depends on the percentage of hardener used. Low percentage hardener produces specimens more flexible with a slightly oily texture. Higher percentage produces specimens completely dry but more rigid. Specimens present no oozing of remnant silicone and can be handled without gloves. More than 500 high quality gross anatomical specimens (figure 4) have been plastinated at room temperature according to this protocol and have remained stable for up to 5 years.

The histological study via light microscopy shows that cellular structure is preserved after plastination at room temperature.

Chemical processes are related to temperature. Cold temperature affects the speed of the plastination process. Also there is danger of ice-crystal formation within cells at -25°C or -30°C if the tissue is not properly precooled. Compared with dehydration by freeze substitution in acetone at -25°C, the method of dehydration by a graded series of acetone solutions at room temperature can be faster as specimens are degreased during this time.

Dehydration at room temperature avoids buying of an explosion proof deep freezer or rebuilding a commercial freezer for the safety by removing the motor and compressor (Gubbins, 1990). It only requires some stainless or plastic containers with tight fitting lids.

Most plastination laboratories use an acetonometer to measure purity of acetone which is based on the buoyancy forces using Archimedes principle. As acetone density is temperature dependent, measuring must be carried out at standard temperature (usually 15 to 20°C). Therefore cold acetone must be warmed or too warm acetone must be cooled to the standard temperature. The scale acetonometer usually requires 250ml of acetone for one measurement. A new acetonometer (figure 1) using an electric principle is available. It is safe, accurate and not temperature dependent. Its compact construction renders it easy to use and portable. We just have to insert the probe tip of the acetonometer into the acetone- water solution and push a button. Indicator lights show the following concentrations of acetone: 100%, 99%, 98%, 95%, 90%, 85%, 80% and 50% within 2 to 3 seconds at any working temperature. It is constructed with low voltage explosion proof electronic circuits. Fast and accurate measurement minimizes exposure to acetone vapors and provides a health benefit.

Silicone reaction mixture remains less viscous at room temperature, permitting faster penetration and easier acetone gas bubbles escape. This permits complete impregnation in 1/3 the time.

The only pieces of equipment needed for the pre- impregnation step are some stainless or plastic containers (without lid) big enough to permit immersion of the dehydrated specimens. We also usually need some assistance from a weight or frame to maintain the whole specimens completely submerged into the silicone solution.

Room temperature forced impregnation only requires a vacuum chamber and a vacuum pump. No freezer is necessary which may limit the size of the vacuum chamber. Our stainless vacuum chambers (figure 2) are mobile and very convenient for the impregnation of any size specimens.

During forced impregnation the balances between silicone solution and acetone within the cells and tissues are broken many times by the intermittent vacuum process. We believe this benefits the escape of acetone from the deep part of specimens and the penetration of silicone to the deep part of the tissues. The intermittent forced impregnation also reduces significantly the work of the pump and a less expensive pump may be used.

Many complete impregnations were achieved with simple rotary vane vacuum pumps whose pumping speed is 8L/sec. Since acetone vapors may damage plastic components and rubber seals of the vacuum pumps, plastic parts and rubber seals were replaced by metal material and silicone rubber. After rebuilding, these vacuum pumps were used for more than one and one half years without any problems. The pressure in the large vacuum chamber could be lowered to 7.5mm Hg in 30 minutes by these inexpensive pumps.

Dehydration and impregnation, performed at room temperature as well as in the cold, need to be acheive in a well ventilated laboratory. Performing these steps at room temperature reduces capital costs and improves safety by reducing the potential hazard of explosion caused by acetone vapor accumulated in a freezer that is not designed for completely spark-proof operation. The intermittent vacuum procedure also reduces capital costs of high quality vacuum pump.

Plastination laboratories use large amounts of acetone for dehydration. Dealing with the used acetone solution is a problem for most managers of plastination laboratories. In order to protect our environment and reduce operation costs, it is recommended to recycle used acetone in our laboratories. Simple devices for the recycling of acetone in plastination laboratories have been proposed before (Grondin and Berube, 1992; Grondin et al., 1997) but were not judged adequate for big volumes of acetone. We designed an acetone recycling equipment. This apparatus (figure 5) made by the Nanjing Su-Yi Plastination Factory consists of four parts. The first part is a stainless container equiped with a oil heating system to heat the used acetone. The second part is a collecting container with a cooling system that cools down the acetone vapors and condenses them into pure liquid acetone. The third part is a control box which controls the oil heating system at the relative stable temperature about 90-110°C. This heat the used acetone at 70 to 90°C permitting a rapid evaporation of the acetone without boiling of the water that is contained. The fourth part is a vacuum generating system that leads the acetone vapors to the collecting container. The volume of the stainless container is 40L and the recycle ability is 25 liters of pure acetone per hour.

Cook P, Dawson B: Plastination methods used in Auckland, New Zealand. J Int Soc Plastination 10 (1): 32-33,1996. https://doi.org/10.56507/GFZT7748

Glover RA, Henry RW, Wade RS: Polymer Preservation Technology: POLY-CUR. A Next Generation Process for Biological Specimen Preservation. 9th Int Conf Plast, Trois-Rivieres, Quebec, Canada, 1998. Abstract in J Int Soc Plastination 13 (2): 39, 1998.

Grondin G, Berube S: A simple and inexpensive method for recycling used acetone in plastination laboratories. J Int Soc Plastination 6 (1): 17-19, 1992. https://doi.org/10.56507/VRMT8219

Grondin G, Henry RW, Janick L, Berube S: Reclamation of Acetone in Plastination Laboratories: A Simple and Inexpensive Method. Acta Anat 158 (1): 26-29, 1997. https://doi.org/10.1159/000147905

Gubbins RBG: Design of a plastination Laboratory. J Int Soc Plastination 4 (1): 24-27, 1990.

https://doi.org/10.56507/ZXJT8319

Henry RW: Principles of Silicone Plastination. 9th Int Conf Plast, Trois-Rivieres, Quebec, Canada, 1998. Abstract in J Int Soc Plastination 13 (2): 28, 1998.

Henry RW, Brown A, Reed RB: Current Topics on Dehydration. 9th Int Conf Plast, Trois-Rivieres, Quebec, Canada, 1998. Abstract in J Int Soc Plastination 13 (2): 27, 1998.

von Hagens G: Heidelberg Plastination Folder. Anatomisches Institut, Universitat Heidelberg, Heidelberg, Germany, 2nd ed, 1986.

Zheng TZ, Weatherhead B, Gosling J: Plastination at room temperature. J Int Soc Plastination 11 (1): 33, 1996.

https://doi.org/10.56507/EHWO1033

Zheng TZ, Xuegui Y, Jingren L, Kerming Z: A Study on the Preservation of Exhumed Mummies by Plastination. J Int Soc Plastination 13 (1): 20-22, 1998. https://doi.org/10.56507/TBQA9451

Zheng TZ, Liu J, Zhu K: Plastination at Room Temperature. 9th Int Conf Plast, Trois-Rivieres, Quebec, Canada, 1998. Abstract in J Int Soc Plastination 13 (2): 29, 1998. https://doi.org/10.56507/YSHV9792

Zheng TZ, Liu J, Zhu K: A Study on Preservation of Ancient Corpses Using the Technique of Plastination. 9th Int Conf Plast, Trois-Rivieres, Quebec, Canada, 1998. Abstract in J Int Soc Plastination 13 (2): 33, 1998.

Zheng TZ, Liu J, Zhu K: Plastinated Specimens for Further Dissections. 9th Int Conf Plast, Trois-Rivieres, Quebec, Canada, 1998. Abstract in J Int Soc Plastination 13 (2): 35, 1998.