Centre for Anatomy and Molecular Medicine, Sigmund Freud Private University, Vienna, Austria.

There are two common methods for carrying out plastination with silicone polymer: cold-temperature impregnation (at -15 to -25°C) or impregnation at room temperature. The standard Biodur technique is the cold impregnation method, although some plastinators prefer to impregnate at room temperature. The aim of our study was to determine the viscosity of standard Biodur® silicone mixtures under different temperature conditions, in order to determine the optimum impregnation time.

Two standard silicone mixtures were prepared: S10/S3, and S15/S3. Each silicone mixture was then divided into 3 equal parts in order to determine the viscosity at -25°C, room temperature (+20°C), and +40°C. Measurements of viscosity were carried weekly, for four weeks, using a rotary viscometer.

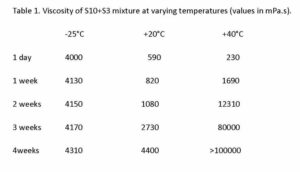

The initial viscosity of S10/S3 at -25°C was 4 000 mPa.s, and it remained almost the same for the next 4 weeks. At room temperature, the viscosity reached 4 000 mPa.s after 4 weeks. At +40°C this value was reached after 10 days.

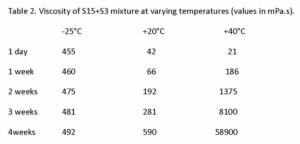

The viscosity of the S15 mixture at -25°C increased to 455 mPa.s after one day and remained almost constant through the next 4 weeks. At room temperature the viscosity reached 400 mPa.s after 3 weeks, and at +40°C it increased to 400 mPa.s after 8 days.

Impregnation at room temperature is possible with both S10 and S15. For the S10 method, an impregnation period of 2 weeks would be recommended, With S15, impregnation at room temperature could be carried out over a period of 1 week, which would be possible for advanced plastinators. However, it is not recommended to plastinate nervous tissue at room temperature.

S10, S15, viscosity, cold impregnation, room temperature impregnation.

Mircea-Constantin Sora, M.D., Ph.D. 'Centre for Anatomy and Molecular Medicine, Medical School, Sigmund Freud Privatuniversität Wien, Kelsenstr. 2, Room 407, A-1020 Wien, Austria, Tel: 43 1 9050070 100

E-mail: constantin.sora@med.sfu.ac.at

![]()

Plastination was developed for teaching as well as for research. In 1977, at the Department of Anatomy, Heidelberg University, Dr. von Hagens invented plastination as a ground-breaking technology for preserving anatomical specimens with reactive polymers (von Hagens, 1979). The S10 technique is the standard technique in plastination. Specimen impregnation with Biodur® S10 results in opaque, more or less flexible, and natural looking, anatomically correct specimens. The goal of plastination is to replace tissue fluid with a curable polymer. Once the polymer is inside the cellular matrix of the specimen, the polymer is cured (hardened) to keep the silicone in the specimen and to make the specimen dry.

All over the world there are two common ways for using the silicone technique: cold-temperature impregnation at (-15 to -25°C) or impregnation at room temperature. The standard technique is the cold impregnation method, at -15 to -25°C, but since the mid-nineties, the room temperature impregnation technique has been developed by Corcoran Industries in the USA. The basic difference in methodology is the sequence in which polymer, catalyst chain extender, and cross-linker are combined. The standard cold Biodur® S10 method combines the silicone polymer with the catalyst and chain extender to serve as the impregnation-mixture (von Hagens, 1986), but the Dow™/Corcoran/ room-temperature method combines the silicone polymer with the cross-linker (Glover et al., 1998, 2004).

Both processes utilize crosslinking of the silicone molecules for hardening the polymer mix. But chain extension is a great advantage of the cold methodology since chain extension commences upon mixing of the polymer (S10) and catalyst/chain extender (S3). The elongated chains allow some flexibility of the cold-mix impregnated specimens. However, chain extension increases the viscosity of the polymer-catalyst mix. Increased viscosity makes the silicone-mix difficult to enter the specimen and hence is a limiting factor with the cold temperature-mixture. Very little chain extension occurs with the room temperature-mixture. Therefore, the room-temperature impregnation-mixture remains very fluid and promotes impregnation.

The main technical disadvantage of the standard S10 technique is the low temperature, which necessitates a deep freezer. The question that arises is: can the S10 Biodur® method be carried out at room temperature?

Our study refers to the standard Biodur® S10/15 techniques. As previously mentioned, the standard protocol uses low temperature for impregnation. However, some plastinators prefer to impregnate at room temperature, for a variety of reasons. The aim of our study was to determine the viscosity of the Biodur® silicone (S10+S3 and S15+S3) mixtures under different temperature conditions, in order to determine the optimum impregnation time.

Two reaction-mixtures were prepared according to the standard protocol of the Biodur® S10/15 technique (De Jong and Henry, 2007). Two silicone mixtures were prepared: 1kg S10 with 10 ml S3, and 1kg S15 with 10 ml S3. The silicone/S3 mixtures were then divided into 3 equal parts for each polymer-mixture, in order to determine the viscosity at i) -25°C, ii) at room temperature (+20°C), and iii) at +40°C. An equal volume of each polymer-mixture was poured into 3 receptacles, and measurements of viscosity were carried out using a rotary viscometer NDJ-1 (Green Technology, China).

The measurements were carried out at -25°C, +20°C and +40°. As three weeks is the standard impregnation time for the cold silicone method, the viscosity of the S10 and S15 mixtures was measured after 1 week, 2 weeks, 3 weeks and 4 weeks.

The standard cold Biodur® silicone technique is performed at -15 to -25°C. In order to determine the viscosity of our Biodur® silicone samples, we carried out measurements at -25°c, +20°C and +40°. As three weeks is the standard impregnation time for the cold silicone method, we measured the viscosity of the S10 and S15 mixture after 1 week, two week, 3 weeks and 4 weeks. At low temperature the initial viscosity of S10 Biodur mixture increased to 4 000 mPa.s and remained almost the same through the next 4 weeks. At room temperature the viscosity reached 4 000 mPa.s after 4 weeks. At +40°C this value was reached after 10 days. For the S15 silicone mixture the viscosity behaved similar to the S10 Biodur® silicone. At low temperature, the viscosity of the S15 mixture increased to 455 mPa.s after a day and remained almost constant through the next 4 weeks. At room temperature a viscosity of 400 mPa.s was reached after 3 weeks, and at +40°C the viscosity increased to 400 mPa.s after 8 days. The results of the measurements are presented in Tables 1 and 2.

|

|

In order to obtain dry plastinated specimens after cold impregnation, the curing stage hardens the polymer. During curing, the impregnation reaction-mix within the specimen is cross-linked, and the specimen becomes dry. This is a two-step process, consisting of chain-extension and cross-linkage of the polymer. Chain extension of the silicone molecules is an end-to-end alignment, thus forming longer molecular chains via the chain extender portion (Biodur S3) of the impregnation-mixture. Theoretically, chain extension starts as soon as the Biodur S3 (catalyst & chain extender) and Biodur S10 or S15 polymer are mixed. However, this reaction is slowed dramatically by cold temperature (below -15°C). The polymer reaction-mixture may be kept for several years in the cold (below -25°C). Longer chains result in more viscous polymer. At room temperature (RT), elongation occurs at an increased rate, and in a matter of months at RT, the reaction-mixture will become too viscous for normal impregnation.

Cross-linking, or connecting the silicone polymer molecules side-to-side, forming a firm 3-D meshwork of the silicone polymer, is brought about by the Biodur® S6 (cross-linker). The catalyst (S3) prepares the S10/S15 molecules to react with the S6 cross-linker. The S6 is more reactive in its vaporized (gaseous) state, hence the term "gas curing" is used. The vaporized S6 diffuses onto the surface of the impregnated specimen. The cross-linking reaction starts on the surface of the specimen and proceeds inward to the depths of the specimen (De Jong and Henry 2007).

In the standard Biodur® silicone method, chain elongation develops during impregnation. The impregnation time in the standard low-temperature S10/S15 protocol is three weeks. This time period permits the vacuum to be increased slowly without the reaction-mixture getting too thick. By mixing S3 with the S10/S15, the polymer chains extend and are thus prepared for the final curing procedure with S6. The difference between the S10 and S15 is in their relative viscosities. The Biodur S10 silicone (MSD 2001/58/EG) has a viscosity of 400-600 mPa.s (at RT) and the Biodur S15 (MSD EG Nr. 1907/2006), a viscosity of 50-60 mPa.s (at RT). This means that the S15 silicone is ten times more fluid than the S10 (water at 20°C has a viscosity of 1 mPa.s). More fluidity suggests that the S15 has shorter polymer chains than the S10 silicone, so we would expect the shelf-life of S15 to be longer. The S15 polymer is used mainly for archeological specimens, hair-covered specimens and viscera, and is not recommended for musculoskeletal specimens. The most common plastination polymer worldwide is Biodur® S10, and this polymer is recommended for anyone starting to do plastination.

It is well-known that after mixing S10 and S3 the mixture starts to become more viscous. The use of low temperature prevents premature thickening of the silicone-mixture, but there is a great disadvantage: the viscosity of the silicone-mixture will also increase with the decrease in temperature. While the room temperature viscosity of S10 is between 400 - 600mPa.s, and for S15 is 40 - 60 mPa.s, at -25°C, the viscosity of both S10 and S15 when mixed with S3, increased 10 times. As the standard protocol for the S10/S15 techniques is carried out at -15 to -25°C, the viscosity of the S10-mix is 4000-6000 mPa.s (like a maple syrup) and for the S15-mix is 400-600 mPa.s (like melted wax at 90°C), as the standard impregnation viscosities. Hence, impregnation with S15 is much easier.

When using low temperature impregnation (-25°C), the viscosity of the S10 and S15 mixtures does not increase a lot after one month, so we can be sure that under these conditions the initial viscosity of the silicone-mixture will remain almost the same during the first three weeks of impregnation.

At +20°C (room temperature), the starting viscosity of the impregnation-mixture is lower than in cold temperature. After one month, the viscosity of the S10 mixture is about 4400 mPa.s and the S15 mixture has a viscosity of 590 mPa.s. This indicates that the S10 has thickened, but is still suitable for impregnation.

At +40°C, the starting viscosity of the impregnation-mixtures was lower, 20 mPa.s for S15 and 200 mPa.s for the S10. After four weeks the viscosity of S15 rose to 59000 mPa.s and the S10 to over 100000 mPa.s (like very thick syrup) and could not be measured. Both values indicate that at this temperature the thickening of the silicone was such that impregnation would not be possible. According to our measurements, after 1 week the viscosity of S15 was 200 mPa.s, and approximately 1700 mPa.s for S10. Under these conditions, impregnation would be possible for both silicone mixtures for a very short time. After 2 weeks, the viscosity rose and reached 12310 mPa.s for S10, which would make impregnation impossible. After 2 weeks, the viscosity of the S15 mixture was 1375 mPa.s and after 3 weeks 8100 mPa.s, which would make impregnation impossible.

The basic principles of vapor pressure of the solvent/acetone need to be understood. To impregnate a specimen, the vapor pressure of the acetone must be overcome so that the acetone can vaporize and be extracted from the cells of the specimen. At low temperature (-25°C), the vapor pressure of acetone is about 14 mmHg. This means that the pressure in the plastination kettle must be lowered nearly one atmosphere, in order to vaporize and remove the acetone which will make room for the silicone-mix to enter the specimen. . (http://ddbonline.ddbst.de/AntoineCalculation/AntoineCalculationCGI.exe?component=Acetone).

However, at 20°C, acetone vapor pressure is 200 mmHg. Therefore, pressure only needs to be lowered two-thirds of an atmosphere to extract the acetone and allow the specimen to be filled with silicone impregnation-mix. This means that acetone will be extracted earlier and faster at room temperature. This fact needs to be correlated with the viscosity of the silicone. At low temperatures, its viscosity is higher, so the extraction of acetone must be slower to allow sufficient time for the more viscous polymer to enter the cells of the specimen; while at room temperature, extraction of acetone may be faster, due to the lower viscosity of the silicone-mixture which can enter the cells more easily.

Considering both parameters, acetone extraction and viscosity, shows that with Biodur® silicone, impregnation at room temperature is possible (Nelson, 1990, DeJong and Henry, 2007). For the S10 method, an impregnation period of 2 weeks would be recommended, with close supervision of acetone extraction. With regard to S15, impregnation at room temperature could be carried out over a period of 1 week. For advanced plastinators, an impregnation process of 1 week would be possible (as the viscosity of the silicone mixture is still low, only 10% of the S10). However, generally it is not recommended to plastinate nervous tissue at room temperature.

De Jong K, Henry RW. 2007: Biodur S10/15 technique and products. J Int Soc Plastination 22:2-14

https://doi.org/10.56507/ZLMJ7068

Glover RA, Henry RW, Wade RS. 1998: Polymer preservation technology: Poly-Cur. A next generation process for biological specimen preservation. Abstract presented at The 9th International Conference on Plastination, Trois-Rivieres, Quebec, Canada, July 5-10, 1998. J Int Soc Plastination 13:39

Glover R. 2004: Silicone plastination, room temperature methodology: Basic techniques, applications and benefits for the interested user. Abstract presented at The 12th International Conference on Plastination, Murcia, Spain July 11-16, 2004. J Int Soc Plastination 19:7

http://ddbonline.ddbst.de/AntoineCalculation/AntoineCalculationCGI.exe?component=Acetone accessed 30/3/2107

Nelson ML. 1990: Developing a plastination laboratory for a new medical curriculum. J Int Soc Plastination 4: 10

https://doi.org/10.56507/ZXJT8319

S10 BIODUR® Products GmbH, Material Safety Data Sheet according to EG Nr. 58/2001.

S15 BIODUR® Products GmbH, Material Safety Data Sheet according to EG Nr. 1907/2006.

von Hagens G. 1979: Impregnation of soft biological specimens with thermosetting resins and elastomers. Anat Rec 194: 247-255.

https://doi.org/10.1002/ar.1091940206

von Hagens G.1986: Heidelberg Plastination Folder: collection of technical leaflets for plastination. Biodur Products, Rathausstrasse18, Heidelberg, 69126. pp2:1-6, 3:1-13, 4:1-20, 5:1-17.